Inside the Electric Beast: Exploring Internal High-Voltage Components of Electric Cars

Sep 11,2023 | TCcharger

Electric vehicles (EVs) are changing the way we think about automotive technology and sustainability. At the heart of every EV lies a complex system of high-voltage components that make these eco-friendly machines move. In this blog post, we'll delve deep into the world of electric cars and explore the internal high-voltage components that power them.

The battery pack is the heart and soul of an electric car. It's where electrical energy is stored and converted into the power needed to drive the vehicle. These battery packs consist of thousands of individual lithium-ion cells grouped together. They're typically arranged into modules, and multiple modules are combined to create the complete battery pack. The high-voltage DC (direct current) energy stored in the battery pack is the primary source of power for the electric vehicle.

Inverter

The inverter plays a crucial role in an electric car by converting the DC power from the battery pack into AC (alternating current) power. Most electric motors operate on AC power, so the inverter is responsible for transforming the voltage and frequency to match the motor's requirements. It ensures that the electric motor receives the right power supply to drive the wheels efficiently.

Electric Motor

The electric motor is what propels an EV. High-voltage power from the inverter is sent to the electric motor, which, in turn, generates the mechanical power needed to drive the wheels. Electric motors in modern EVs come in various configurations, including permanent magnet motors, induction motors, and synchronous reluctance motors, each with its own advantages in terms of efficiency and performance.

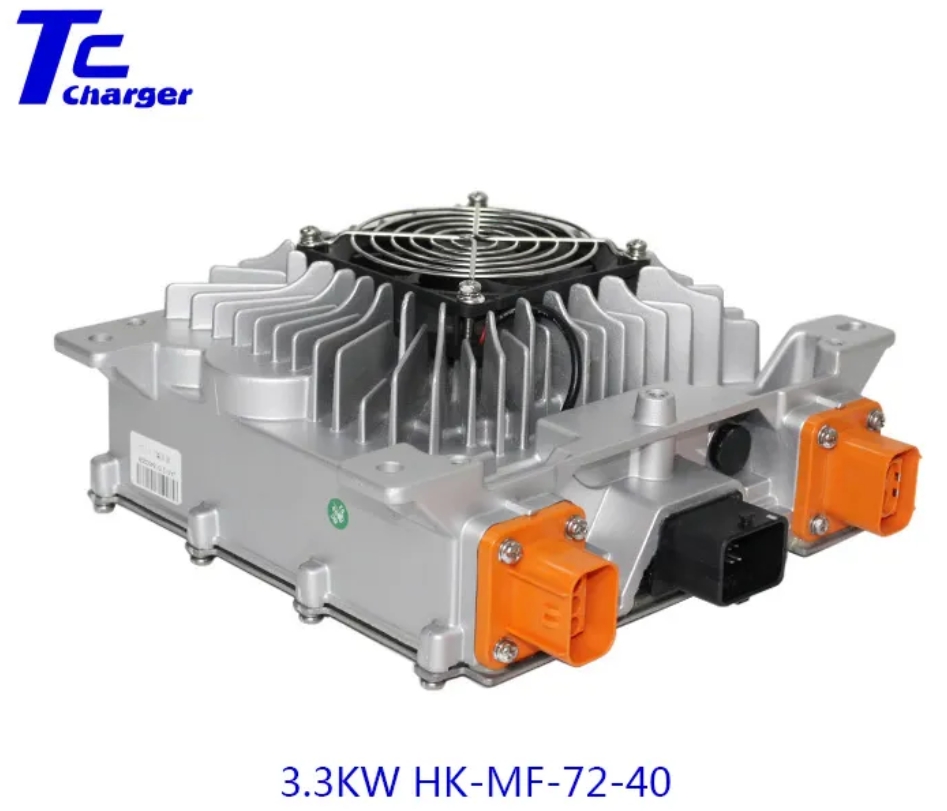

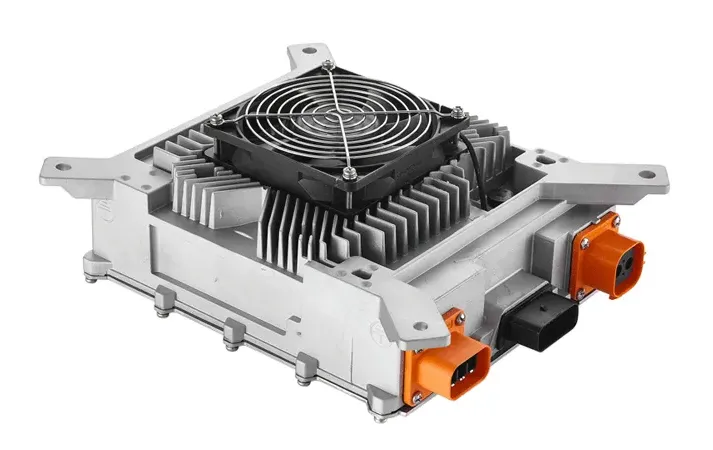

Charging System

EVs are designed to be charged from external power sources, such as charging stations or home chargers. The charging system within an electric car includes components like the charging port, onboard charger, and charging control unit. The high-voltage DC power from external sources is converted into the appropriate voltage and current levels by these components to safely charge the battery pack.

Electric vehicles have a 12V electrical system similar to traditional internal combustion engine vehicles for powering auxiliary systems like lights, infotainment systems, and HVAC (heating, ventilation, and air conditioning). The DC-DC converter takes high-voltage DC power from the battery pack and steps it down to the 12V needed to power these systems, ensuring that they continue to function while the vehicle is in operation.

High-Voltage Wiring and Insulation

High-voltage components are connected through specialized high-voltage wiring and connectors. These components are designed to handle the high voltage and current associated with electric propulsion systems. Additionally, high-voltage wiring is carefully insulated to prevent electrical shorts and ensure the safety of passengers and maintenance personnel.

Safety Systems

Electric cars are equipped with sophisticated safety systems to protect against high-voltage accidents. These systems include high-voltage disconnect switches that can isolate the battery pack in case of emergencies, as well as sensors and circuitry that monitor the electrical system for faults and anomalies.

Conclusion

Electric cars are technological marvels, and their high-voltage components are at the core of their exceptional performance and environmental benefits. As the EV industry continues to advance, these internal components will become even more efficient, powerful, and integrated, driving us closer to a sustainable and electrified future of transportation. Understanding the key high-voltage components of electric cars helps us appreciate the complexity and innovation behind these vehicles and their potential to revolutionize the automotive industry.